PROJECT

Worldwide Projects

The tunnel boring machines of JIM TECHNOLOGY CORPORATION, a global company,

are proudly delivered to over 30 countries around the world.

Asia

-

- WORLD

PROJECT - 01

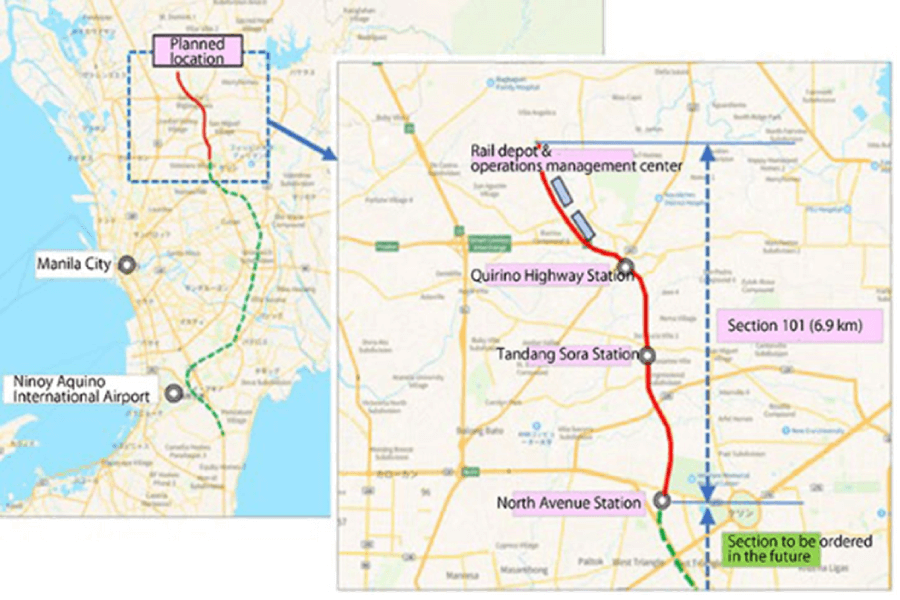

Manila Urban Subway Project CP101 Construction Zone

- Project No.

- #3760

- Client

- Department of Transportation (Philippines)

- Customers

- Shimizu-Fujita-Takenaka-EEI-Joint Venture

- About the machine

- This is a boring machine with a diameter of φ6.99 m. It was delivered for the Manila Urban Subway Project CP101 Construction Zone, the first subway project to be underway in the Republic of the Philippines. Six mud earth load shield machines were used to construct six subway tunnels for a total length of 9.5 km. Excavation with the first machine started in January 2023. This construction has garnered attention from the citizens of the Manila Metro Area as it is the first subway construction project in the Philippines, and there are high hopes that this subway will be the key to reducing traffic congestion.

Data sheet

- Region

- Manila, Philippines

- Construction period

- From 2022

- Purpose

- Subway (Metro Manila Subway)

- Soil

- Sandstone, Siltstone, Gravel & Boulders, Clayer Sand, Silty Sand, Clayer/Inorganic Silt, Elastic Silt, Poorly graded Sand, Poorly graded Gravel

- Construction distance

- Total length of 9,494 m (1,509 m x 2, 1,458m x 2, 1,780 m x 2)

- Machine data

- Earth Pressure Balance

Machine diameter: φ6.99 m

Lining: RC segment

Cutter power: 924 kW

Cutter torque: 6,307 kN/m

Effective thrust: 48,000 kN

- WORLD

-

-

- WORLD

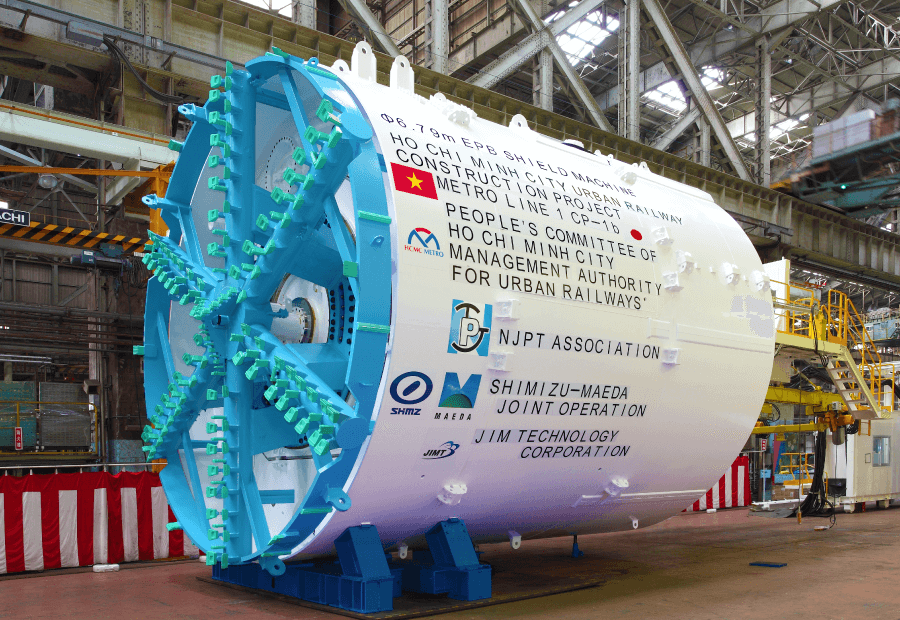

PROJECT - 02

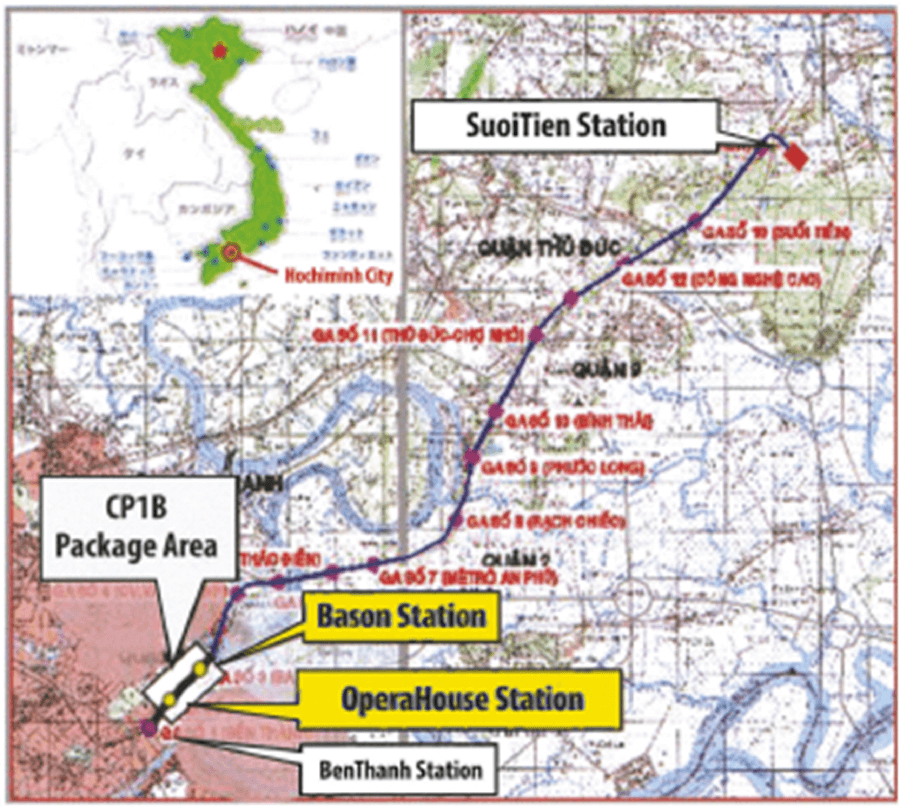

Ho Chi Minh City Urban Railway Line 1 CP1B Construction Zone Project

- Project No.

- #3673

- Client

- Ho Chi Minh City Citizens Committee, Urban Railway Management Organization

- Customers

- SHIMIZU-MAEDA JOINT OPERATION

- About the machine

- This is a boring machine with a diameter of φ6.79 m. It was delivered for the Ho Chi Minh City Urban Railway Line 1, as the first subway shield tunnel in Viet Nam. The shield tunnel construction area was a length of 781 m x 2 areas (from the Opera House Station to Ba Son Station). Excavation of the first construction area began in May 2017, and excavation of the second area was completed in July 2018.

Data sheet

- Region

- Ho Chi Minh, Viet Nam

- Construction period

- 2017 to 2019

- Purpose

- Subway (Ho Chi Minh Subway)

- Soil

- Sand, silty sand

- Construction distance

- Total length of 1,562 m (781 m x 2)

- Machine data

- Earth Pressure Balance

Machine diameter: φ6.79 m

Lining: RC segment

Cutter power: 675 kW

Cutter torque: 6,485 kN/m

Effective thrust: 40,000 kN

- WORLD

-

-

- WORLD

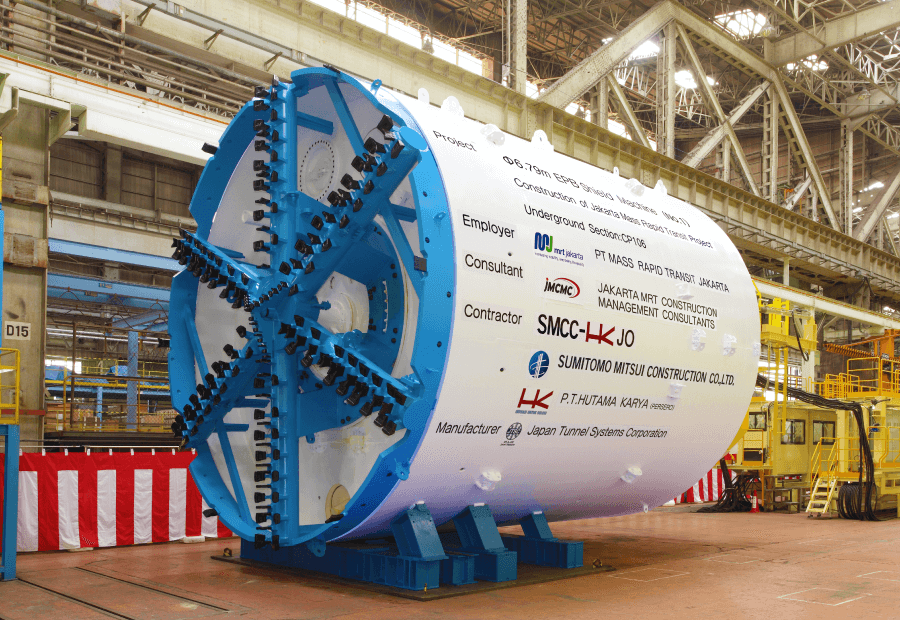

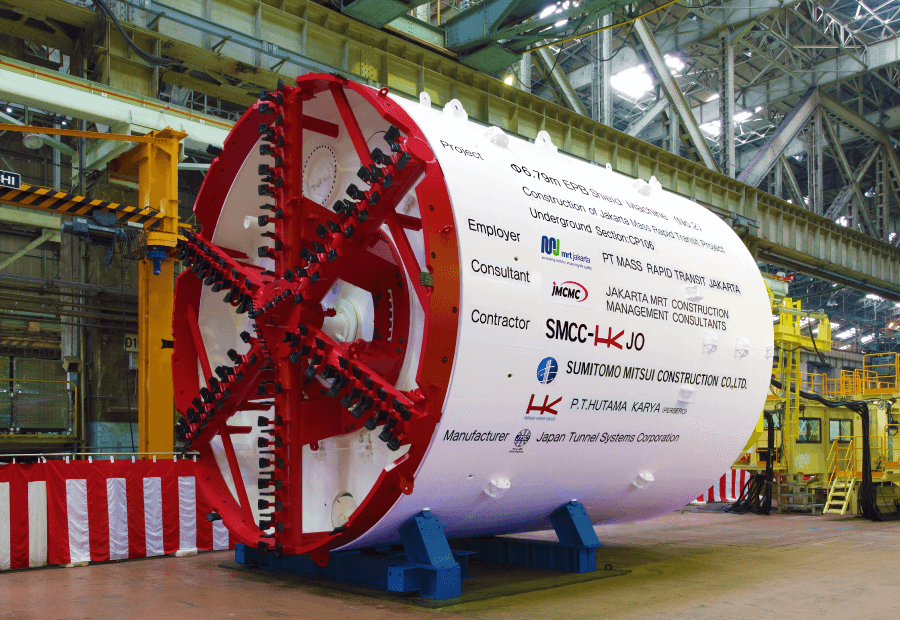

PROJECT - 03

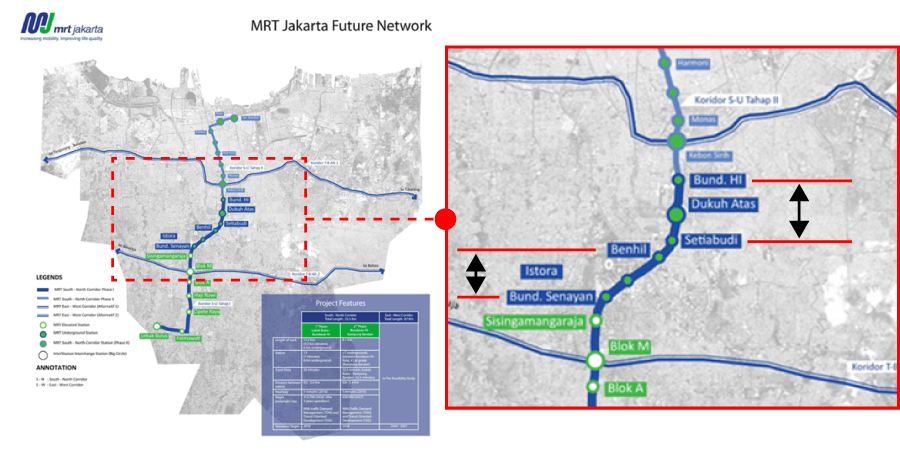

Jakarta High-Speed Railway Construction CP106 Construction Zone

- Project No.

- #3623-3624

- Client

- Jakarta High-Speed Railway Company

- Customers

- SUMITOMO MITSUI CONSTRUCTION / HUTAMA KARYA JOINT OPERATION

- About the machine

- This is a boring machine with a diameter of φ6.79 m. It was delivered for the Jakarta Urban High-Speed Railway (MRT North-South Line), the first subway in Indonesia. A total of four shield machines were delivered, including two mud earth load shield machines that were used for this construction in a total length of 15.7 km (approximately 6 km underground), which connects the center of Jakarta from north to south. The MRT North-South Line began operation in March, 2019. This line was opened with the aim to create a modal shift from automobile transport to public transit, and it is expected to respond to increasing demand for transport, reduce traffic congestion, improve investment environments, and reduce burdens on the environment.

Data sheet

- Region

- Jakarta, Indonesia

- Construction period

- 2016 to 2017

- Purpose

- Subway (Jakarta Subway)

- Soil

- Hard cohesive soil, sandy silt, silty sand, sand

- Construction distance

- Total length of 2,744 m (1372 m x 2)

- Machine data

- Earth Pressure Balance

Machine diameter: φ6.79 m

Lining: RC segment

Cutter power: 660 kW

Cutter torque: 6,283 kN/m

Effective thrust: 40,000 kN

- WORLD

-

-

- WORLD

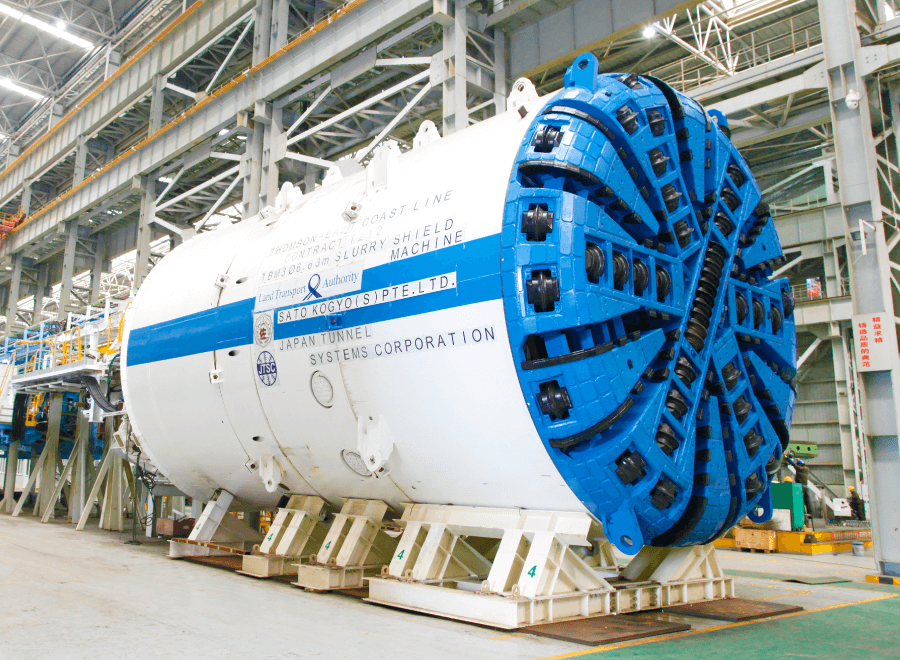

PROJECT - 04

Singapore Thomson Line T212 Construction Zone

- Project No.

- #3619

- Client

- Singapore Land Transportation Authority

- Customers

- Sato Kogyo (S) Pte. Ltd.

- About the machine

- This is a boring machine with a diameter of φ6.63 m. Three of these machines were delivered for the Singapore Subway Thomson Line. In order to excavate composite ground consisting of a base rock layer (called “ Bukit Timah Granite”) and sand gravel layer, the machines were built with specifications that would allow them to perform high-speed rotation of the cutter heads equipped with multiple disc cutters for excavating rock base. Excavation of earth used a slurry type machine with discharge using a fluid conveyance system.

Data sheet

- Region

- Singapore

- Construction period

- 2016 to 2017

- Purpose

- Singapore (Singapore Subway)

- Soil

- Granite, gravel

- Construction distance

- Total length of 3,840m (560 m x 2, 1,360 m x 2)

- Machine data

- Slurry Shield

Machine diameter: φ6.63 m

Lining: RC segment

Cutter power: 1,500 kW

Cutter torque: 7,170 kN/m

Effective thrust: 48,000 kN

- WORLD

-

-

- WORLD

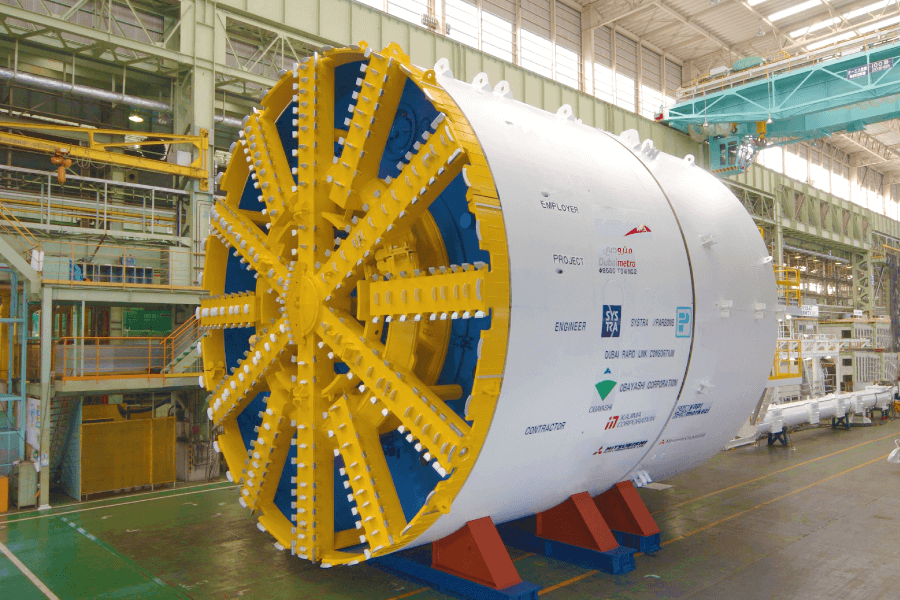

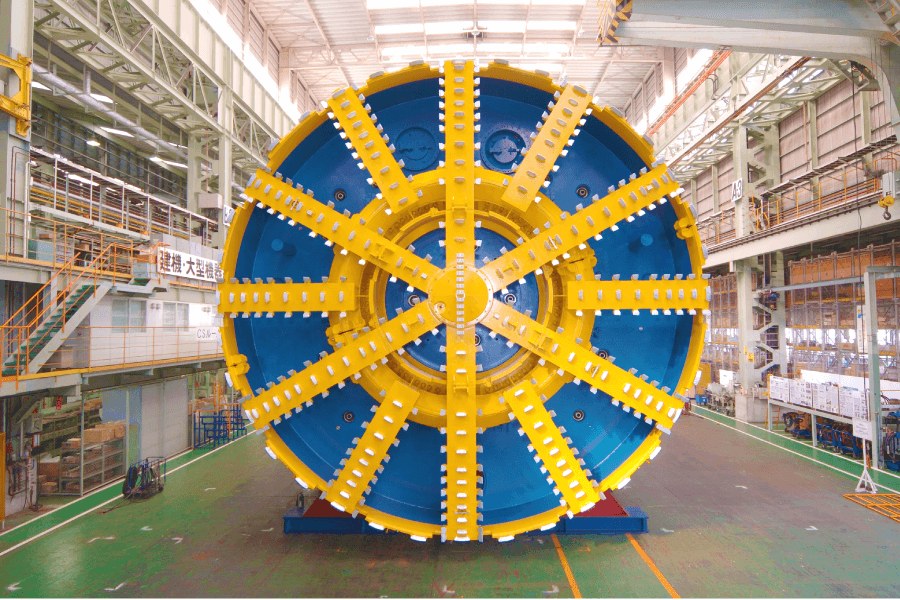

PROJECT - 05

Dubai Metro

- Project No.

- #3274

- Client

- Dubai Municipal Government

- Customers

- Obayashi-Kajima-Yapi Joint Venture

- About the machine

- Dubai in the United Arab Emirates has been facing serious traffic congestion in the city due to its remarkable economic growth and increase in population. What was planned for eliminating this problem was the Dubai Metro, the first urban railway transport system in the Middle East. Three boring machines with a diameter of φ9.56 m were delivered for excavating tunnels with a total length of approximately 10 km. The Dubai Metro started operation in September 2009, and all lines are fully automatic.

Data sheet

- Region

- United Arab Emirates (Dubai)

- Construction period

- 2006 to 2008

- Purpose

- Subway (Dubai Subway)

- Soil

- Upper silty sand , Lower silty sand , Weak rock

- Construction distance

- 10,107m(1479m+2700m, 2226m+1916m, 1786m)

- Machine data

- Earth Pressure Balance

Machine diameter: φ9.56 m

Lining: RC segment

Cutter power: 1,530 kW

Cutter torque: 17,059 kN/m

Effective thrust: 87,000 kN

- WORLD

-

North America

-

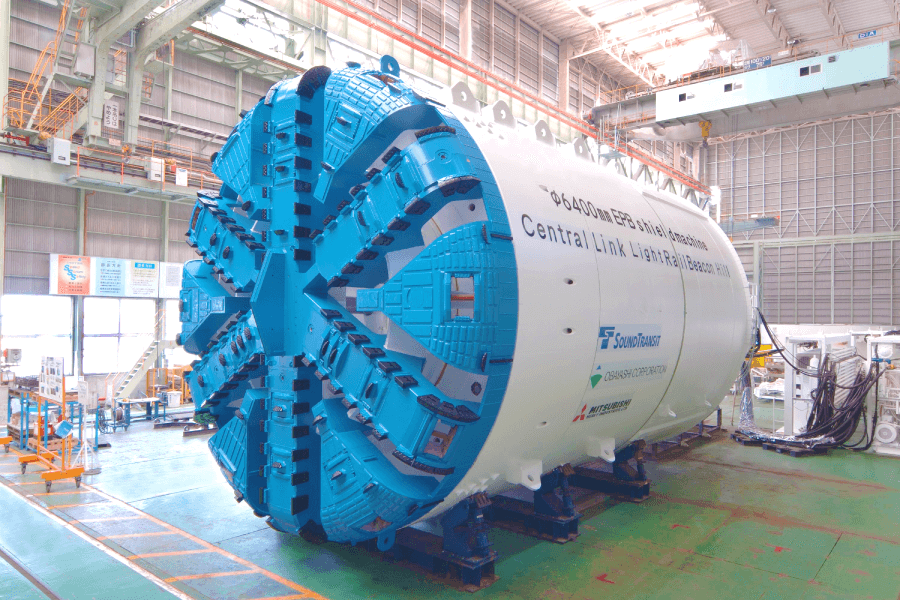

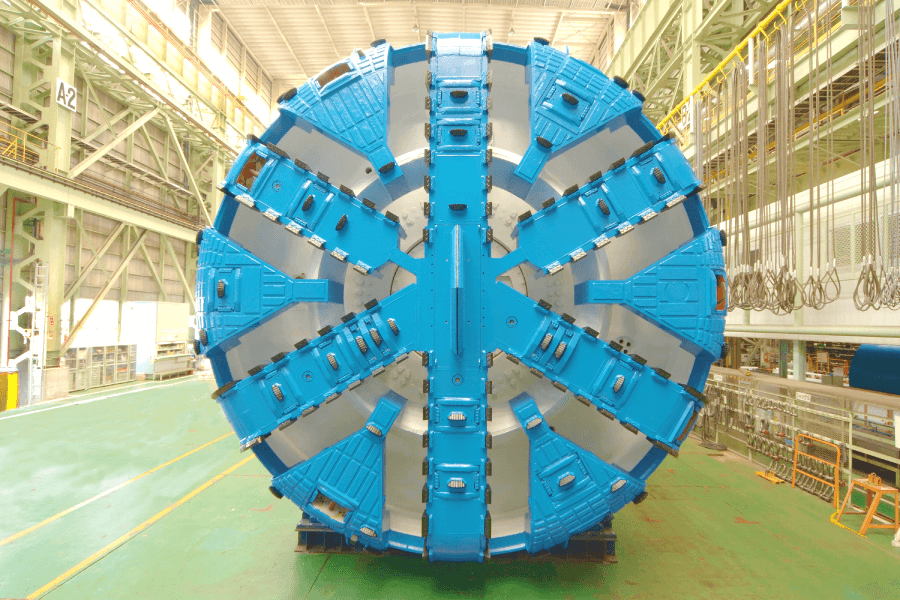

- WORLD

PROJECT - 06

Central Link Light Rail Beacon Hill

- Project No.

- #3202

- Client

- Seattle Sound Transit

- Customers

- Obayashi Corporation

- About the machine

- This is a boring machine with a diameter of φ6.4 m. It was delivered for construction of a shield tunnel in the Beacon Hill construction zone of the light rail that connects Seattle (United States) with Seattle-Tacoma Airport.

Data sheet

- Region

- United States

- Construction period

- 2006 to 2008

- Purpose

- Subway (Seattle Subway)

- Soil

- Clay, stiff clay

- Construction distance

- Total length of 2,598 m ((543 m + 756 m) x 2)

- Machine data

- Earth Pressure Balance

Machine diameter: φ6.4 m

Lining: RC segment

Cutter power: (Hydraulic drive)

Cutter torque: 6,031 kN/m

Effective thrust: 40,000kN

- WORLD

-

Australia

-

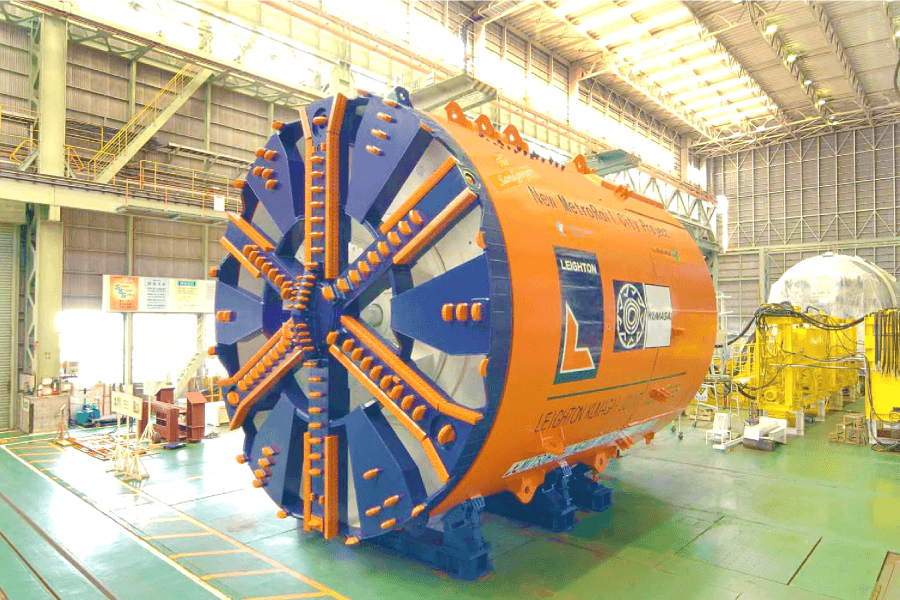

- WORLD

PROJECT - 07

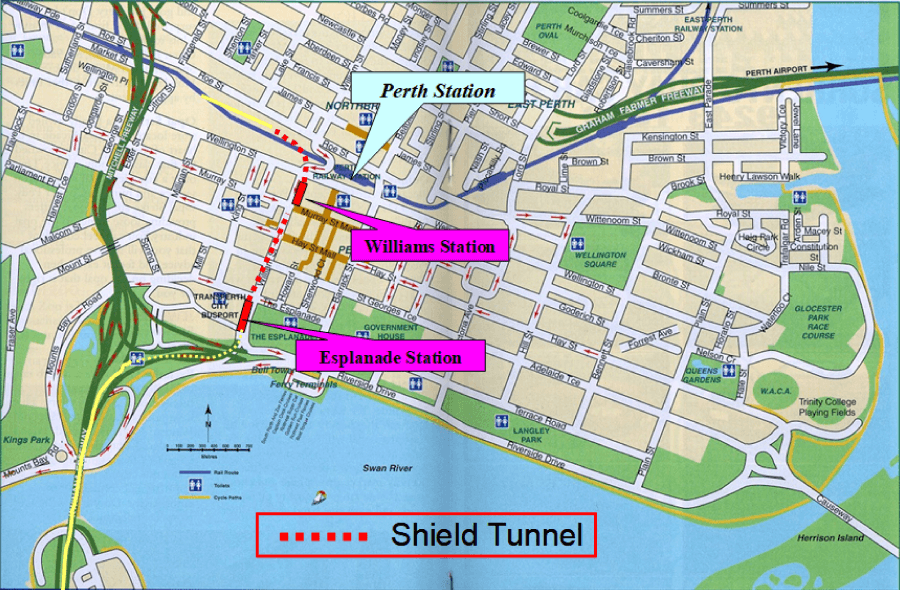

Perth Southwestern Railway Expansion Construction Package F (Transperth - Mandurah line)

- Project No.

- #3149

- Client

- Public Transport Authority of Western Australia

- Customers

- Leighton Kumagai Joint Venture

- About the machine

- This is a boring machine with a diameter of φ6.87 m. It was delivered for a tunnel between Perth Railway Station (* William Street Station) and Elizabeth Quay Railway Station (* Esplanade Station) on the Transperth Mandurah Line, which is a municipal public transport system in Perth, Australia. The machine was given the name of “Sandgroper”, which is the name of an underground insect that lives in Australia. Excavation started in October of 2005 and was completed in October of 2006.

The asterisk refers to the name of the station at the time of delivery.

Data sheet

- Region

- Australia

- Construction period

- 2005 to 2006

- Purpose

- Subway (Perth Subway)

- Soil

- Sand, silty sand

- Construction distance

- Total length of 1,500 m (750 m x 2)

- Machine data

- Slurry Shield

Machine diameter: φ6.87 m

Lining: RC segment

Cutter power: 540 kW

Cutter torque: 5,485 kN/m

Effective thrust: 40,000 kN

- WORLD

-

Europe

-

- WORLD

PROJECT - 08

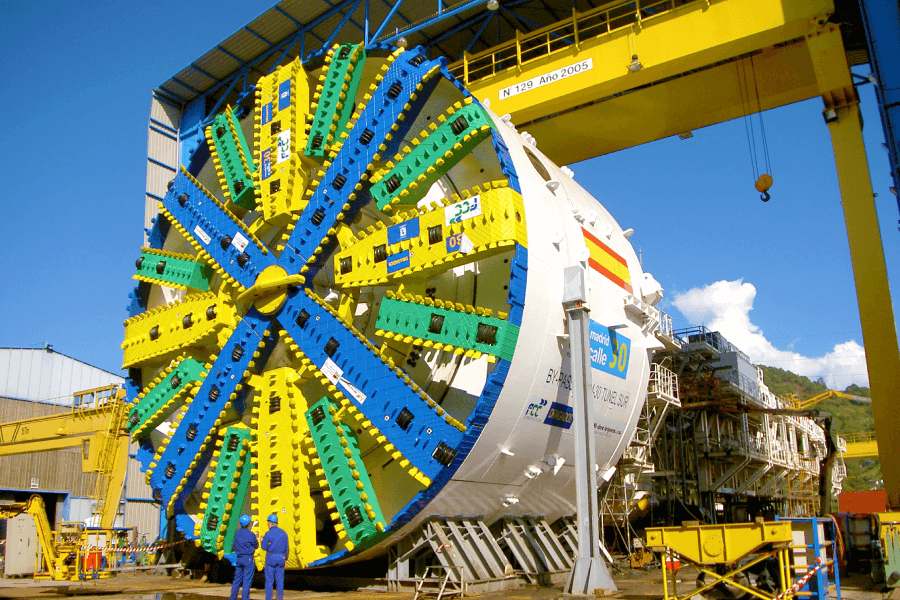

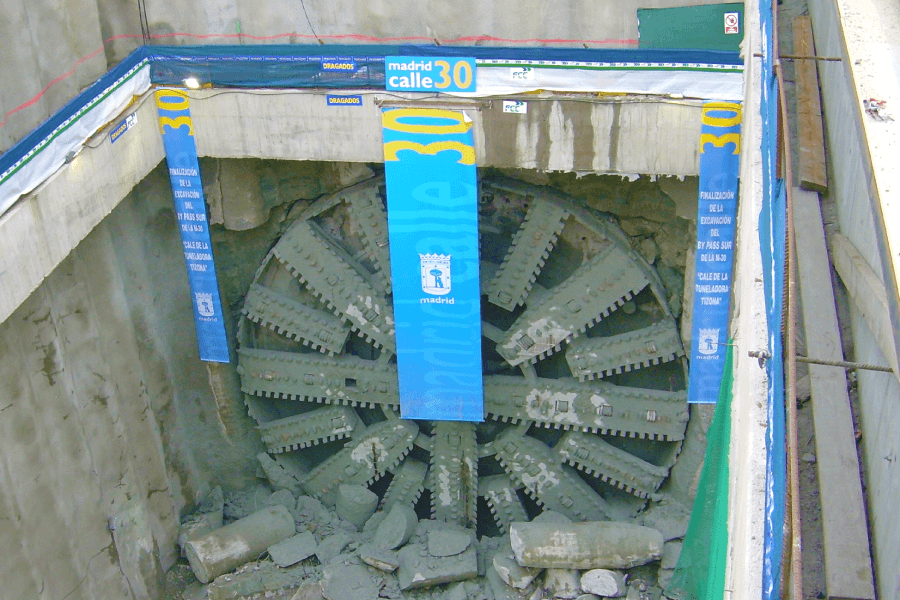

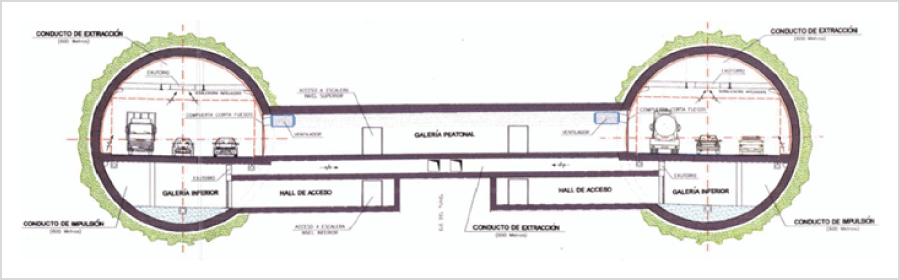

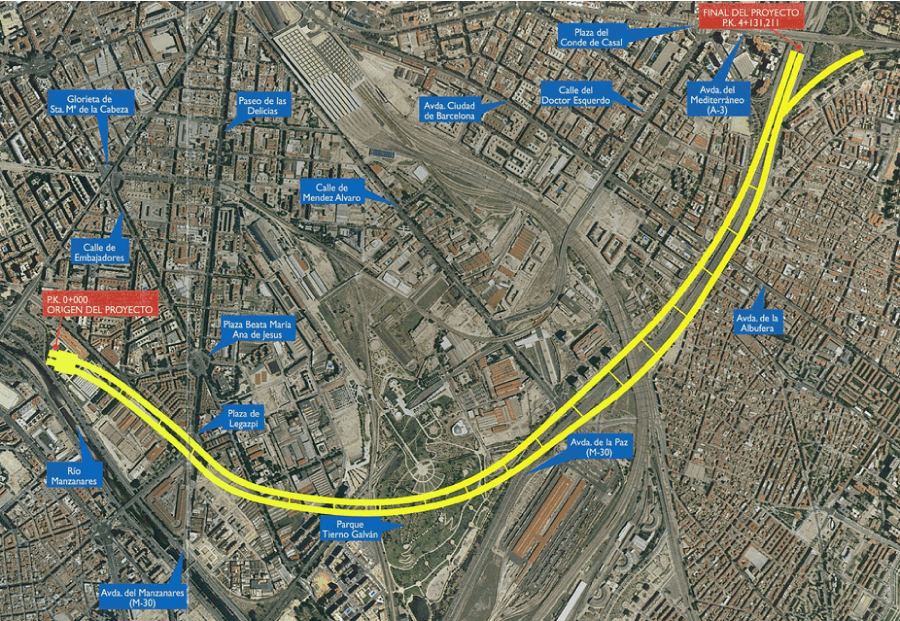

Madrid Orbital Motorway M30 Improvement Construction South Construction Zone Bypass South Tunnel

- Project No.

- #3478

- Client

- Madrid Calle 30

- Customers

- Dragados-FCC Joint Venture

- About the machine

- This is a large-bore-diameter boring machine with a diameter of φ15 m. It contributed to the construction of an expressway tunnel in Madrid. The construction deadline was extremely short, and it required an excavation speed of 360 m a month, so a high-power boring machine was designed and produced. The boring machine was delivered to the site in November 2005. Excavation started in April 2006 and finished in October 2006. The average excavation speed was 534 m a month, with the highest being recorded at 800 m a month. The “M30” orbital motorway, with a length of approximately 35 km through the city of Madrid, faces some problems resulting from increased traffic volume, such as chronic congestion, worsening of the nearby environment due to exhaust gas, and segmentation of the urban area. The tunnel boring machine contributed to solving the issues caused by making the motorway underground.

Data sheet

- Region

- Spain (Madrid)

- Construction period

- 2006 to 2006

- Purpose

- Making a motorway underground

- Soil

- Green and gray litified lutite, Rough clays, Sandy clays Argillaceous sand, Sand clay

- Construction distance

- 3652m

- Machine data

- Earth Pressure Balance

Machine diameter: φ15 m

Lining: RC segment

Cutter power: 10,024 kW

Cutter torque: 26,529 kN/m

Effective thrust: 105,000 kN

- WORLD

-