TECHNOLOGY

Other

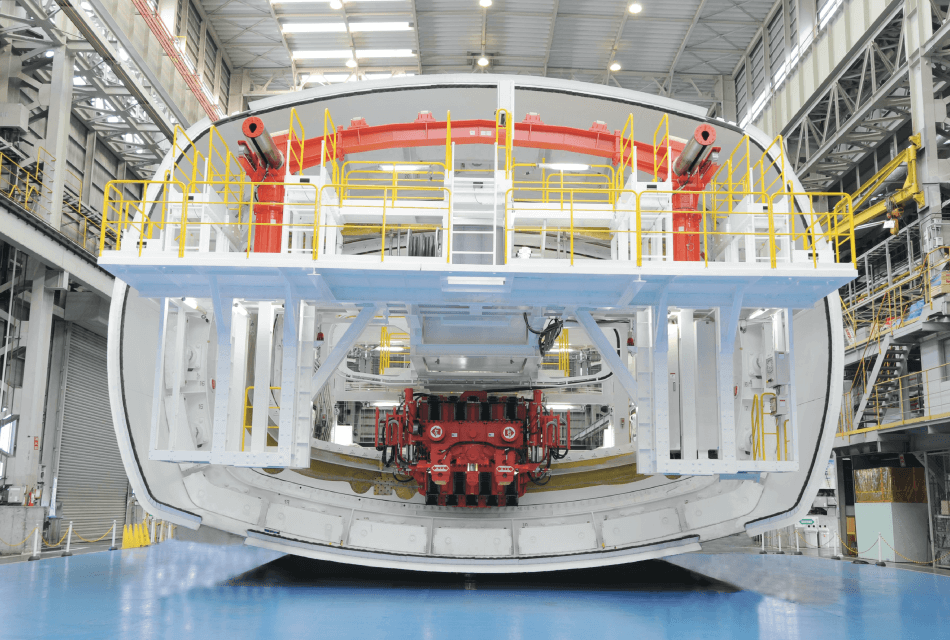

Segment Assembly

-

Automatic Segment Erecting System

Automatic segment erecting system safely and accurately perform automation of tasks involved in the assembly of segments, from delivery of segments to positioning and the connecting of joints. The semi-automatic assembly systems can do the work up to the rough placement of the segment, with the precise positioning and joint connection being performed manually.

-

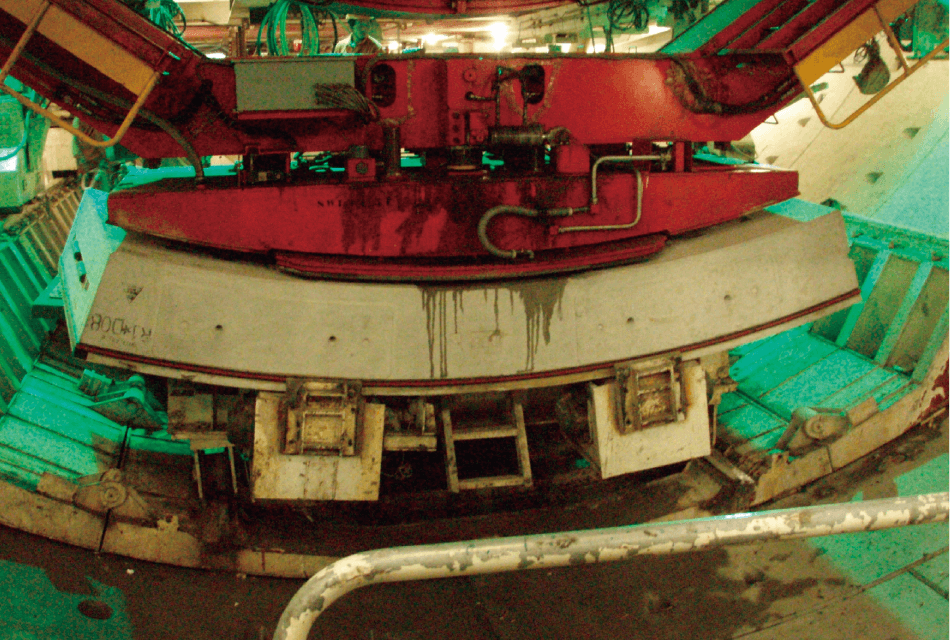

Monorail-type Erectors

Monorail-type erectors enable more efficient assembly of segments having a non-circular section, as T-shaped section rails are installed in alignment with the construction section in the shield machine. Additionally, adopting a structure in which the T-shaped rails float up from the main body helps reduce the impact of deformation of the shield main body due to factors such as external pressure.

-

Segment Vacuum Retention Method

Vacuum equipment installed inside the erector holding part performs suction on the segment that has been set to the holding position of the erector by the feed device in order to keep it in place. Suction continues until assembly of the segment is complete and holding is released.

-

Slewing Type Assembly Scaffolding Equipment

This is scaffolding equipment that can be slewed or slided forwards or backwards so that the manual work of connecting joints in a segment semi-automatic assembly system can be performed safely. Buckets are also available in an optional sliding type.

Shield Rear Equipment

-

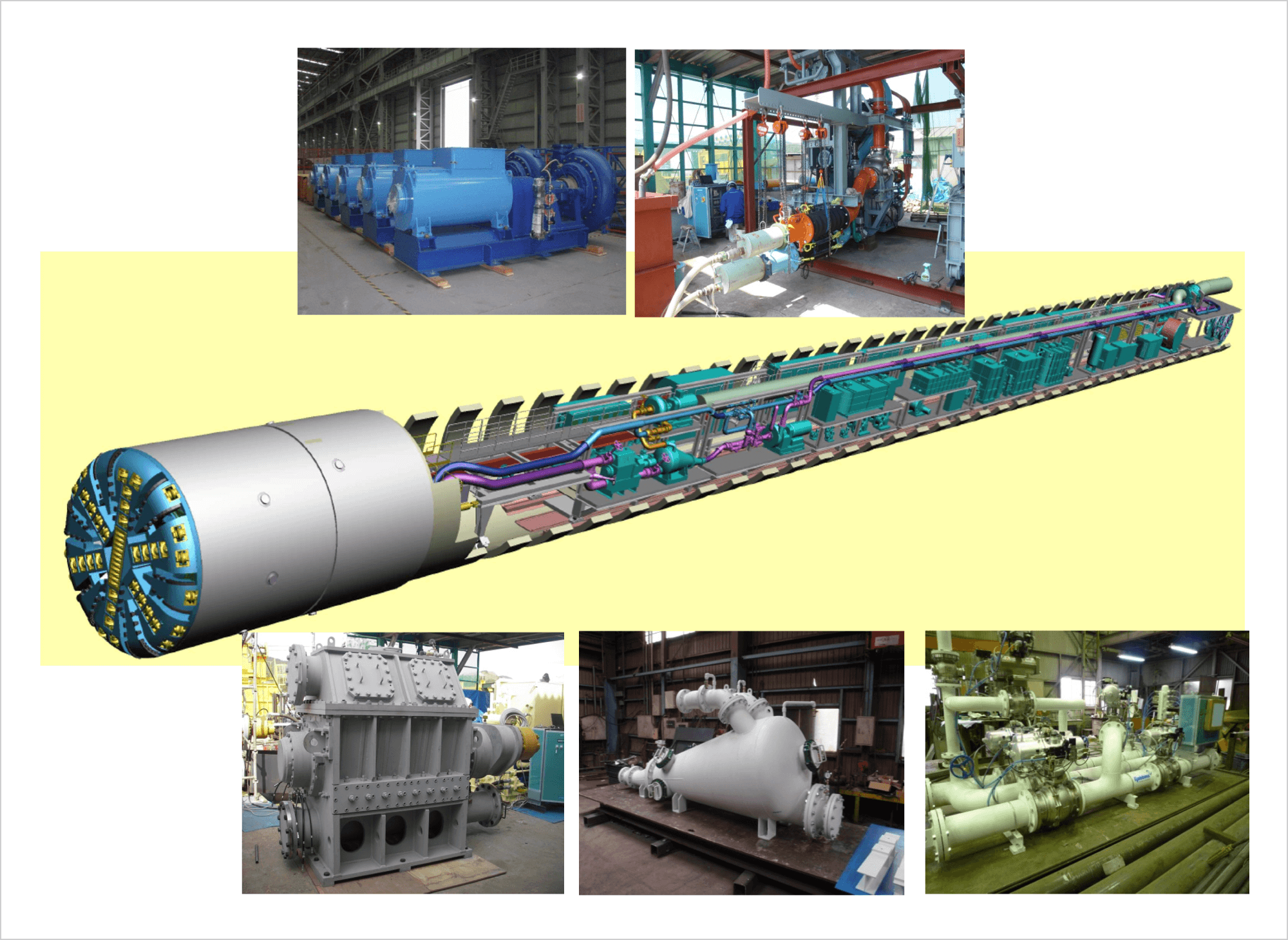

Slurry Transport Equipment

JIMT offers all the equipment required for a slurry shield machine hydraulic system.

-

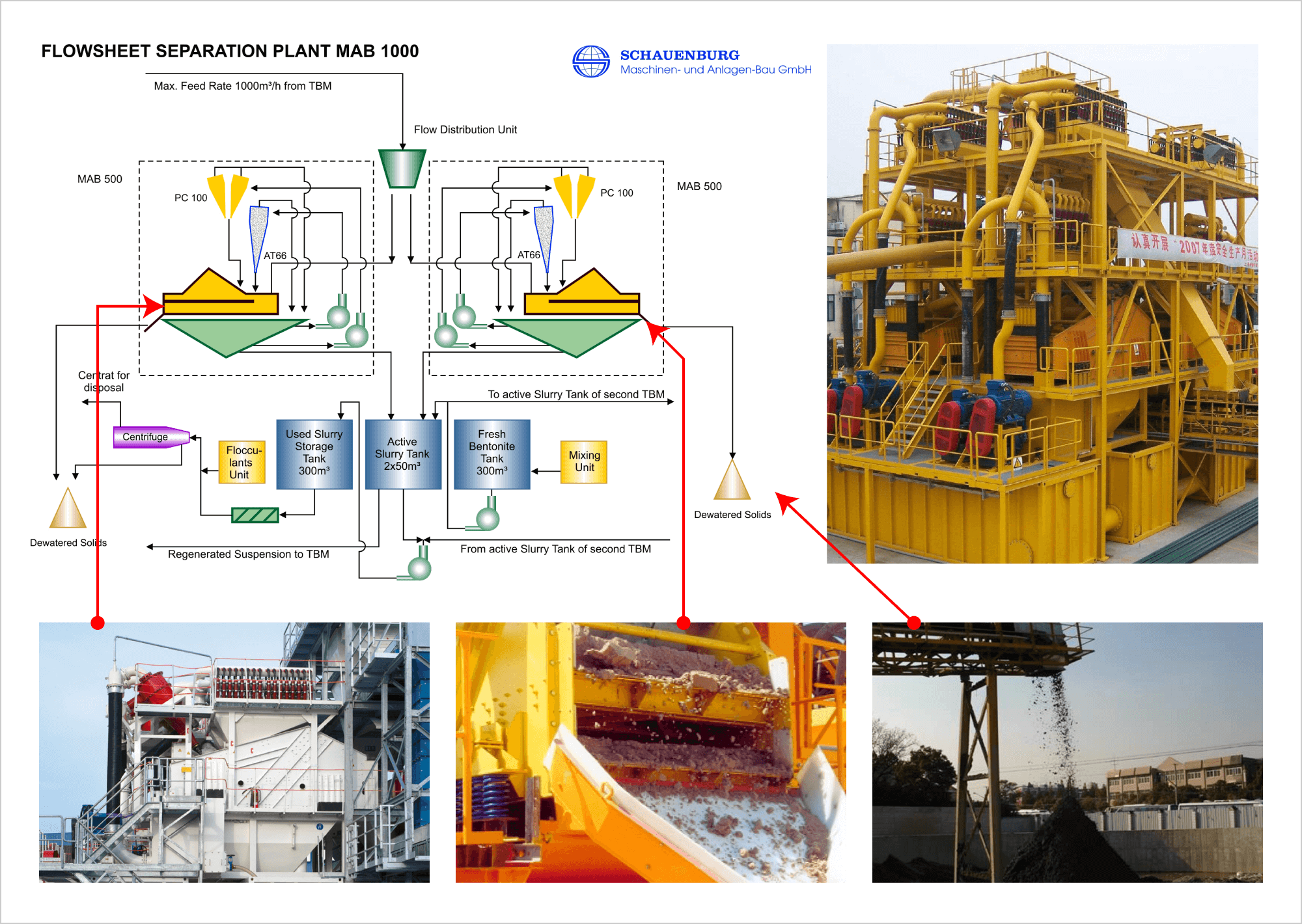

Slurry Processing Plants

JIMT offers all the equipment required for processing plants for slurry shield machine hydraulic systems (such as primary classifiers, secondary classifiers, and equalizing tanks).