PRODUCT

SPECIAL SHIELD MACHINE

The work of excavating tunnels

begins from selecting the most optimal machine for the geology and one which is capable of clearing all work-related restrictions.

Here are some special shield machines that can handle various types of excavation conditions.

Special Shield Machine

-

SENS Method

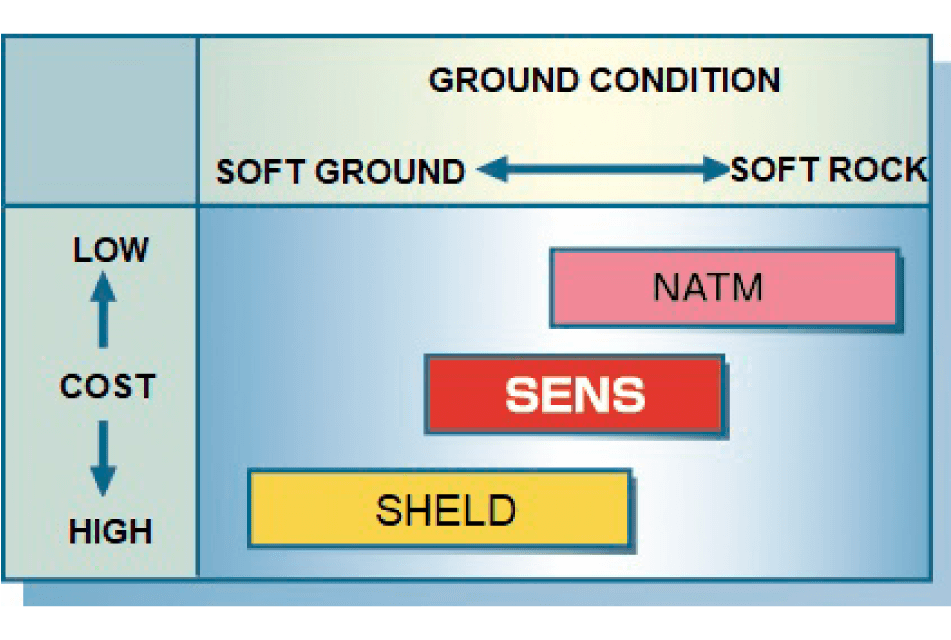

“SENS method” stands for “Shield-ECL-NATM-System” method. In this method, the stability of the face is preserved during excavation using the Shield method. This method does not require segment assembly and the tunneling work can be completed by aiming for a quick closure with initial timbering using the cast-in-place lining method (ECL), and placing concrete for the second lining following displacement and convergence on the ground, in the same manner as NATM sprayed concrete. The φ 11 m class is used for Shinkansen and railway tunnels. We have also released machines with special equipment that allows you to switch between the Shield and SENS method.

SENS is gaining its place as a cost-efficient construction method of boundary regions of NATM and SHELD method, according to the characteristics of the subsoil. It is expected to have major contributions in the future to the fields of large bore diameters and long distances, in particular.

Special Shield Machine (Elimination of Vertical Shaft)

-

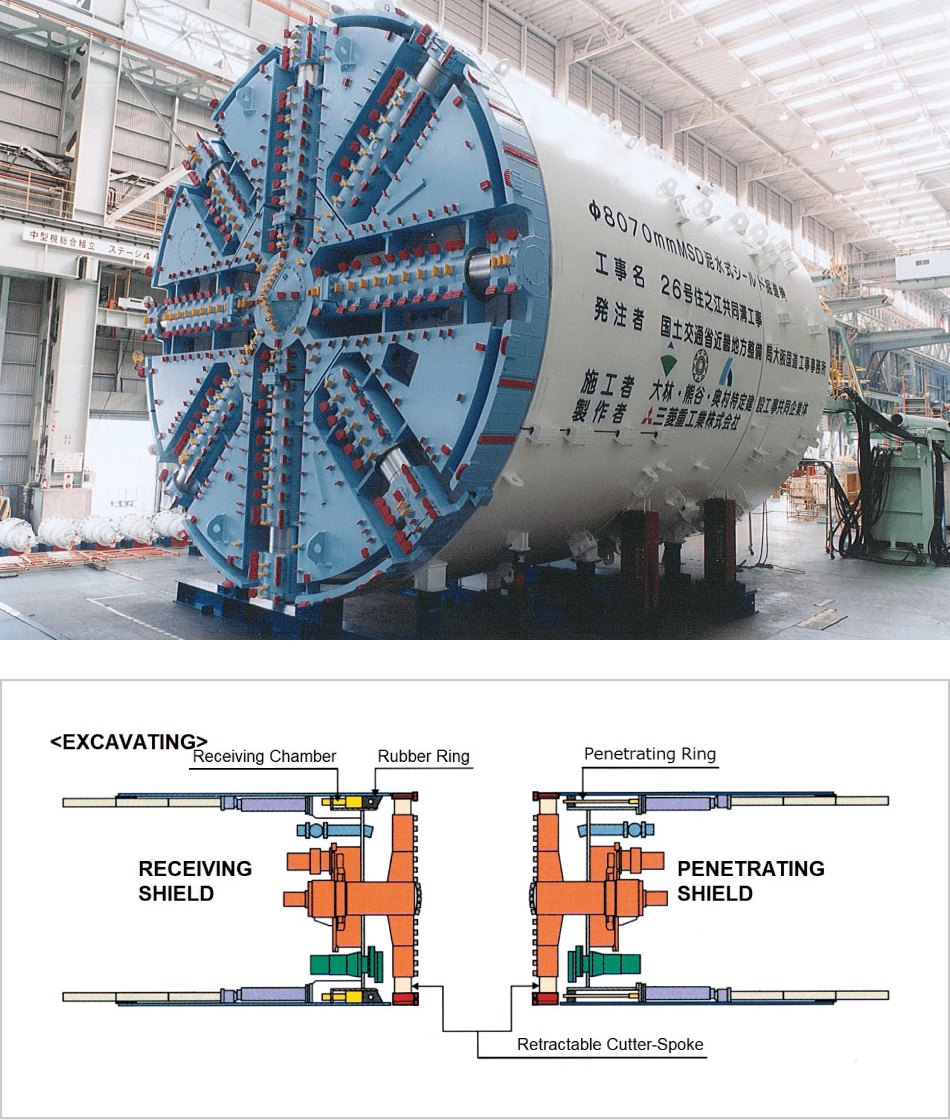

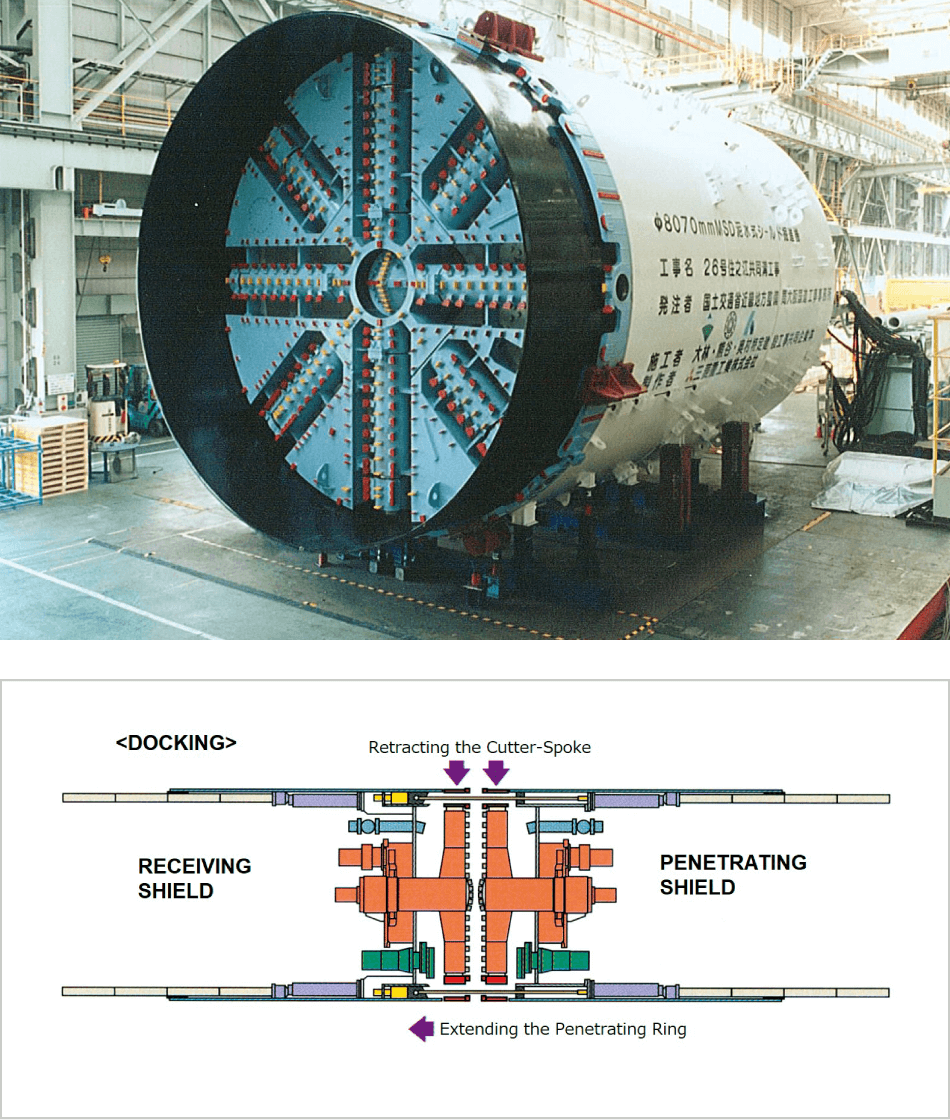

MSD Method

This is a method of joining underground by pushing the steel penetration ring installed in the extruding side into the rubber pressure-receiving ring on the receiving side.

Special Shield Machine (Construction of Vertical Shaft)

-

Upwards Facing Shields

These are shields used for constructing vertical shafts upwards towards the surface from existing tunnels. They can be collected and reinstalled after reaching the surface.

-

Horn Method (Criss-cross Successive Shield Machine)

A single shield machine can successively excavate from the vertical shafts to the horizontal shafts. They also incorporate a vertical shaft excavation function using caissons or continuous underground walls, which were required in conventional construction methods. This made it possible to make the vertical shaft area smaller.

Special Shield Machine (T-BOSS)

-

The steel rings (cutting rings) fitted with cutting bits inside the shield are rotated using the rotary torque of the cutter head. This makes it possible to directly cut and insert existing pipe and mechanically join new tunnels in a T shape.

Special Section Shields (Double Circular)

-

DOT Shields

DOT shields are equipped with multiple spoke type cutters. The cutters are arranged so that they interlock like gears, which prevents simultaneous rotation. This makes it possible to excavate evenly across the entire face.

-

MF Shields

In MF shields, the cutter heads of multiple circular shields are shifted forwards and backwards. Shields where there is partial superimposition are used, which makes it possible to excavate tunnels with sections that have multiple circular shapes.

-

H&V Shields

In H&V shields, a special buckling mechanism is used to buckle multiple front trunks in their respective opposite directions to apply a rotational force to the shield and perform excavation in a spiral fashion. This makes it possible to continuously move between horizontal and vertical tunnels.

Special Section Shields (Variant Sections)

-

The characteristic of this excavation method is in the combination of the main cutters for circular excavation through the center of a section, with swing cutters for excavation in the corners of the circumference. Swing cutters perform excavation through swinging according to stroke adjustment of the hydraulic jack which extends and retracts according to an automatic control method, for each rotational direction of the main cutters. The frequency of the swing cutters can be adjusted for any section shape.

Special Section Shields (Non-Circular)

-

DPLEX (Eccentric) Shields

The cutter frame is operated through parallel linking, which makes it possible to excavate any section, such as squares, ovals, horseshoes, and circles.

-

Expansion Shields

Following soil stabilization around the circumference where the shield tunnel work was performed, the ground is excavated in a circumferential shape along the tunnel circumference in order to expand the tunnel in the prescribed section and concentric circular shape.